| FADING, CHALKING, OXIDIZING. UV Screen printed signs and decals fade, chalk and oxidize MUCH faster outdoors than solvent screen printed signs and decals. The reason is obvious. Solvents screen print inks are put onto sign and decal surfaces MUCH thicker than UV screen print inks. This is possible because solvent screen print inks dry by evaporation, which allows for the MAXIMUM thickness of the ink for the best outdoor durability. Think about it…If you use the same pigment in two inks, and one ink has to be applied with X thickness, and the other ink is applied with 3 times X thickness, which will last longer outdoors, have more scratch resistance, and hold upper better under numerous cleanings? SOLVENT SCREEN PRINTING INK IS APPLIED THICKER THAN UV SCREEN PRINTING INK. Solvent screen print inks are put onto sign and decal surfaces with lower mesh screens that allow the MAXIMUM amount of ink while maintaining fine detail. Solvent screen print inks are put onto sign and decal surfaces with softer squeegees that force a MAXIMUM amount of ink through the screen fabric, while maintaining fine detail. |

|

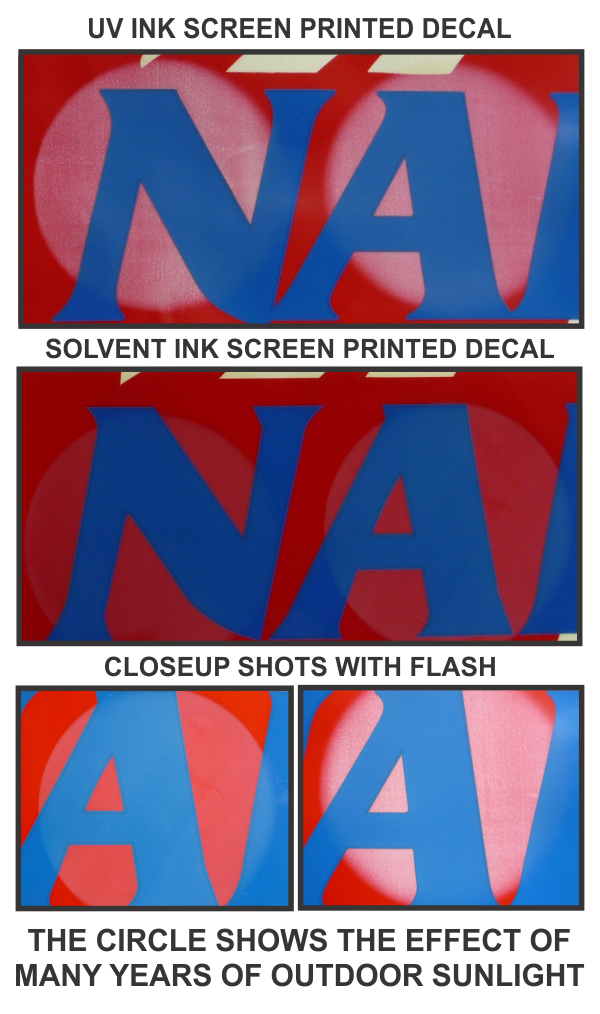

| UV SCREEN PRINTING INK IS APPLIED THINNER THAN SOLVENT SCREEN PRINTING INK. UV screen print inks have to are thinner, so they use higher mesh screens and harder squeegees to keep the thickness of the ink to 1/3rd the thickness of solvent screen print inks. The reason they must be thinner is they must be cured with UV light immediately, so they can be stacked without them sticking together. Thick inks does not cure. I have witnessed the sticking together of products because the ink was too thick. Sometimes this happens in the box after the product sits on the shelf for a time. At Anytime Sign, we had to put a product through the UV conveyor 25 times to get an adequate cure. UV SCREEN PRINTING INK FADES, CHALKS, SCRATCHES AND BREAKS DOWN WITH MULTIPLE CLEANINGS. UV Screen printed signs and decals fade MUCH faster outdoors, do not stand up as well against chalking and scratching, and do not hold up well against multiple cleanings. AGING CHAMBER TEST RESULTS. Compare the deterioration of the solvent screen printed decal versus the UV screen printed decal. The round areas are the areas exposed to the equivalent of many years of sunlight. Look at the flash closeup. The difference in thickness between the UV screen printed ink and the solvent screen printed ink is obviously why the UV screen printed decal is inferior to the solvent screen printed decal. ANYTIME SIGN DOES USE UV SCREEN PRINTING FOR CERTAIN APPLICATIONS Anytime sign has UV screen printing inks and fine mesh screens and harder squeegees and a UV conveyer dryer for jobs where extremely fine detail require UV screen printing. Also, if UV screen printed products are used indoors, they are only inferior to solvent screen printed product because they scratch easier and do not hold up well to numerous cleanings. If a sign or decal is used indoors, and is not frequently cleaned, and is located where it cannot be easily scratched, UV screen printed signs and decals will serve you just as well as a solvent screen printed sign and decals. |

|

Why order from us ?

1) We are the manufacturer * That means no expensive middlemen.

2) Most of our products are manufactured in-house

* That means you get the best price and fastest turn-around.

3) We offer true quantity discounts

* That means prices tied to time & material cost, not what the market will bear.

We might already have your logo on file!

CLICK HERE if you want a corporate or organization sign which includes a logo

|

|